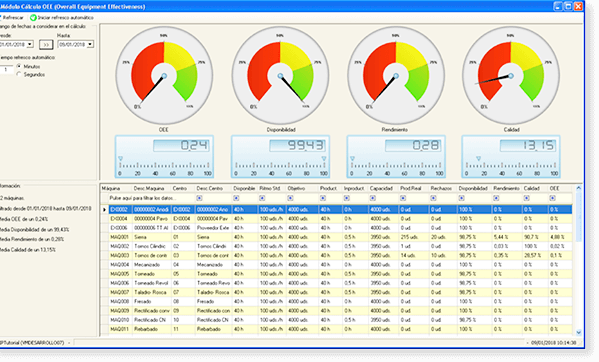

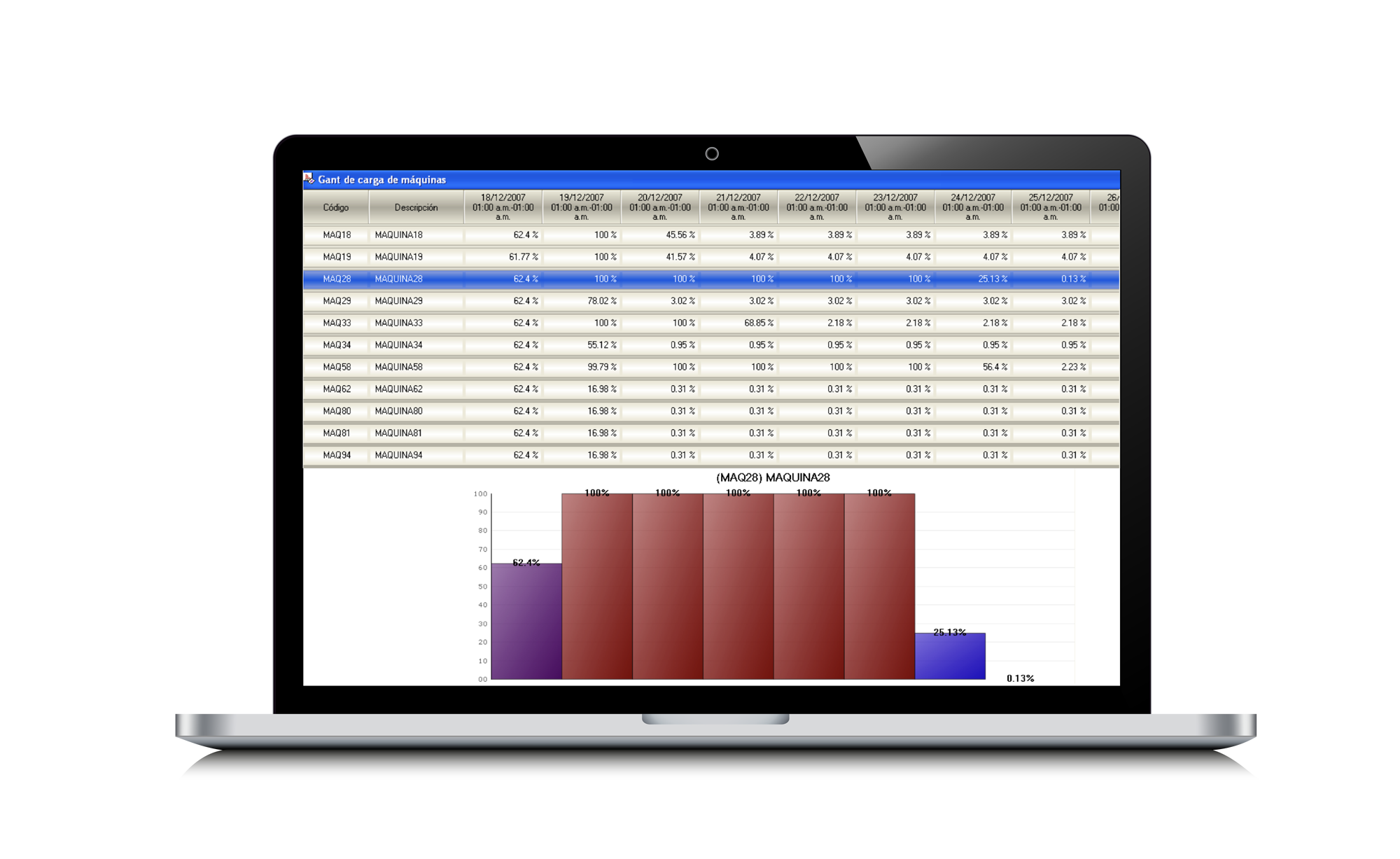

ERP for Manufacturing (MES)

Improve your production control and efficiently manage your business processes. Planning, programming, execution and monitoring of your entire business from the raw material to the final product.